Electroplating for metal ware are a very important part of us. Their quality, functional properties and different usability satisfy wide range of requirements in various customer needs.

In this section you can briefly understand the basic concept of the electroplating stages on Buttoncare ® products.

Silver Plate • Gold Plated • Nickel Plating • Metal Plate • Electroplating Supplies • Brass Plate Company

[ OVERVIEW ]

With the different type of coatings for metalwares, the right selection of a plating coating is very important. It depends on many factors like product type, construction, exposure to different atmospheric and other stress, technologic possibility and other influences that we are able to recognize, also following most up to date trends. That is why only the correctly chosen road, quality surface preparation and application may guarantee a long life span of protected facility and the customer’s satisfaction.

Electro Coatings

Combining Environmentality & Sustainability

Plating is a surface covering in which a metal is deposited on a conductive surface. Plating has been done for hundreds of years; it is also critical for modern technology. It is used to decorate objects, for corrosion inhibition, to harden, to improve wearability, to reduce friction,, and for other purposes. There are several plating methods, and many variations.

ECO Electroplating

Under the Buttoncare ® brand, our most products are processed by ECO electroplating protects the underlying metal from wear and from the attack of corrosive substances and oxidation, and to guarantee the absolute respect of such important aspects it is necessary to rely on our plating partner that offers a guarantee of true expertise and technical assistance combined with a structure and adequate for meeting even the most critical needs.

The safety of the plating layer of Buttoncare ® products is of paramount importance. It can meet a wide range of MSDS recommended standards for major countries for toxic heavy metals, including total Nickel, Lead, Tin, Chromium, Cobalt and Zinc contents, meeting CPSC (CPSIA) and REACH (SVHC) requirements.

Colors & Finishing

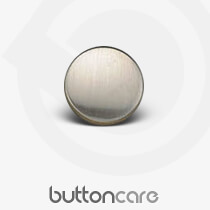

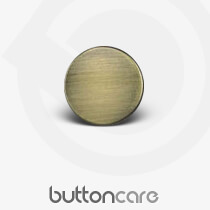

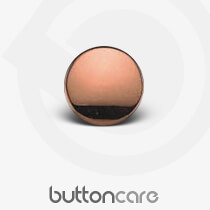

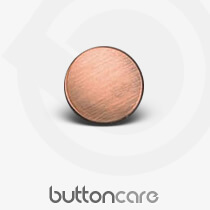

The color plating process combines plating technologies, to produce quality and long lasting finishes to the usual electroplated colors like nickel, gun metal, pure 18K gold or other special surface finishes.

There are various electroplate colors and finishes, hence, we cannot entirely be listed from the page. The following common color examples we choose can help enhance your understanding our basic scope.

https://www.buttoncare.com/electroplating.html#sigProIdfa49507341

| ⚠ *Before using, understand that the colors shown on this site are computer simulations of the colors and may not match Buttoncare identified color standards. Always consult us to visually evaluate any result before utilization. |

The True Quality Of Electroplate Color

We create inspirational colors where every detail is refined. Buttoncare ® colored series opens the door to many new options and combinations for a unique or innovative look on a range of objects. These colored finishes have a matte, glossy and brush finishes. Moreover, it offers complete electroplating process to plate larger and smaller parts which require rack mounting, wire mounting or barrel plating by customer requirements.

Our commitment to quality extends across the board utilizing a collaborative, and most efficient methodologies derived from the body of knowledge in pre-production, production, quality testing and assurance. We are disciplined in creating and maintaining critical process controls and pride ourselves in delivering process capabilities that exceed all of our customer’s expectations.

At Buttoncare ® we are constantly seeking opportunities within quality system to strive for continual improvement.

Click On : PAINT COATING